Smart pipeline Solution

Smart pipeline Solution,It can mark the dense urban underground pipelines and important facilities, thereby accurately, safely and quickly locating them. When used in conjunction with GPS (Global Positioning System) and intelligent mobile terminals, it can conveniently help engineering personnel find the target location and obtain relevant information about the equipment on site.

- Commodity name: Smart pipeline Solution

- Description

-

1. ApplicationSmart pipeline Solution,It can mark the dense urban underground pipelines and important facilities, thereby accurately, safely and quickly locating them. When used in conjunction with GPS (Global Positioning System) and intelligent mobile terminals, it can conveniently help engineering personnel find the target location and obtain relevant information about the equipment on site.The electronic identification system originated in the United States and strictly follows the standards set by APQA (American Public Works Association) for underground facility identification. It is used to mark the routes of underground pipelines and to locate important underground facilities.2. Smart pipeline Solution can solve the detection problems of non-metallic pipelines.Buried non-metallic pipelines cannot be detected by traditional underground pipeline detectors.Moreover, the lifespan of commonly used metal tracer lines is very limited and is much shorter than the service life of non-metallic pipelines. The application of underground pipeline electronic identification systems can effectively solve the problems of detection, location and management of non-metallic pipelines.

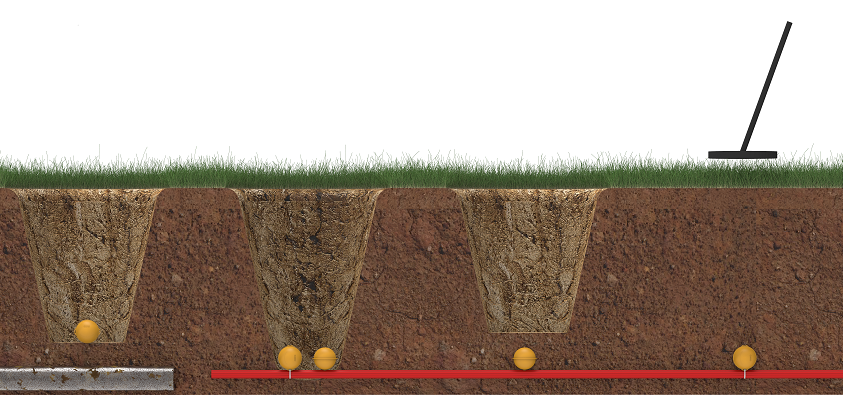

3. Smart pipeline solution detection principleThe detection of underground pipeline electronic markers adopts low-frequency passive RFID technology. The signal can penetrate non-metallic media such as soil, asphalt and concrete. The positioning accuracy can reach 10 cm, which is much higher than that of traditional pipeline detectors. Different types of electronic markers can be selected according to the burial depth, and the maximum burial depth can reach 2.4 meters.1. The detector sends signals of a certain frequency intermittently.2. Underground identifiers with the same resonant frequency absorb and store signal energy.3. After the detector sends signals for a short period of time, it stops sending and enters the signal reception mode.4. The detector measures the strength of the returned signal to determine the exact location of the identifier.5. When the detector is closest to the identifier, the signal is the strongest, which is precisely above the identifier.

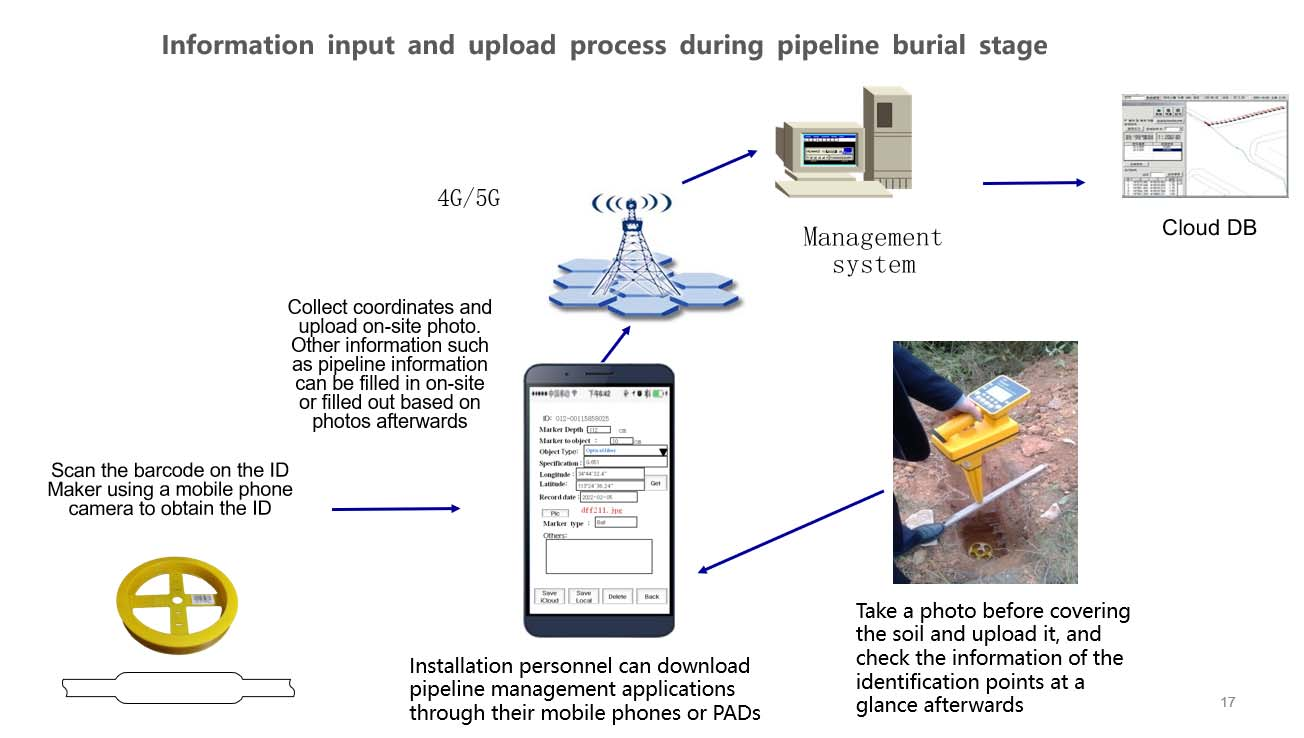

3. Smart pipeline solution detection principleThe detection of underground pipeline electronic markers adopts low-frequency passive RFID technology. The signal can penetrate non-metallic media such as soil, asphalt and concrete. The positioning accuracy can reach 10 cm, which is much higher than that of traditional pipeline detectors. Different types of electronic markers can be selected according to the burial depth, and the maximum burial depth can reach 2.4 meters.1. The detector sends signals of a certain frequency intermittently.2. Underground identifiers with the same resonant frequency absorb and store signal energy.3. After the detector sends signals for a short period of time, it stops sending and enters the signal reception mode.4. The detector measures the strength of the returned signal to determine the exact location of the identifier.5. When the detector is closest to the identifier, the signal is the strongest, which is precisely above the identifier. 4. Composition and Structure of smart pipeline SolutionIt is mainly composed of four parts.1. Electronic Identifier2. Detector3. Mobile terminal APP and applications4. Data service softwareStructure1. The electronic identifier serves as the basic information point and achieves the unique correspondence between data information and physical devices through the ID code.2. At the engineering site, information points can be created through intelligent terminals and displayed in real time on the electronic map.3. Through intelligent terminals, one can directly collect information such as latitude and longitude coordinates, on-site pictures, etc., and upload it to the server.4. The data is stored in the cloud and can be viewed at any time and from any location via smart terminals or web browsers.

4. Composition and Structure of smart pipeline SolutionIt is mainly composed of four parts.1. Electronic Identifier2. Detector3. Mobile terminal APP and applications4. Data service softwareStructure1. The electronic identifier serves as the basic information point and achieves the unique correspondence between data information and physical devices through the ID code.2. At the engineering site, information points can be created through intelligent terminals and displayed in real time on the electronic map.3. Through intelligent terminals, one can directly collect information such as latitude and longitude coordinates, on-site pictures, etc., and upload it to the server.4. The data is stored in the cloud and can be viewed at any time and from any location via smart terminals or web browsers. 5. Advantage OF smart pipeline Solution

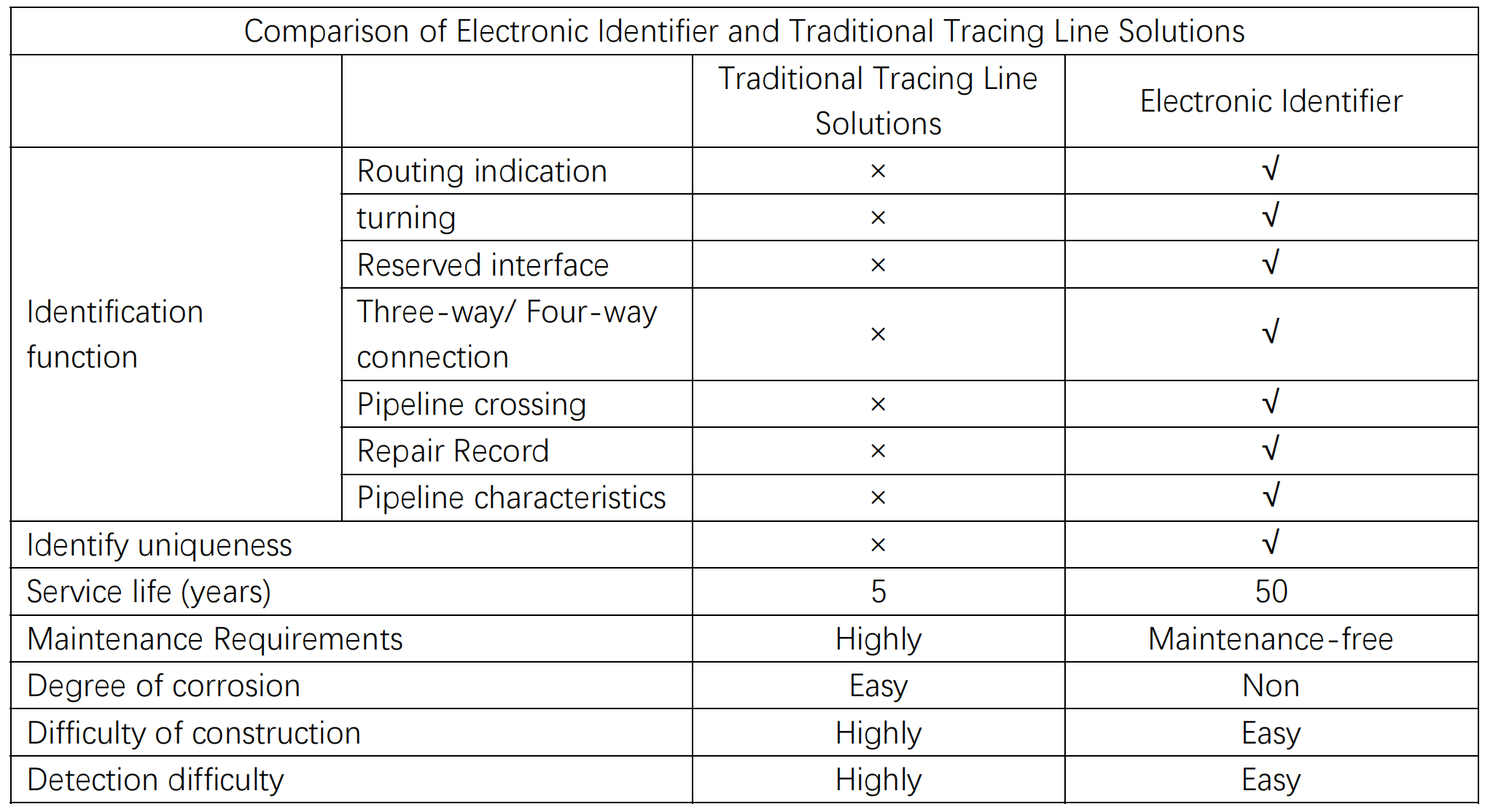

5. Advantage OF smart pipeline Solution The underground pipeline electronic identification system can help operators achieve precise positioning and management of underground assets under non-digging conditions.1. Real-time access to the precise routing system of underground Pipelines.2. Quickly locate the target facilities on-site, such as valves, T-shaped branches, and joints.3. Quickly identify different underground pipelines and facilities.4. Quickly grasp the various complex situations such as the turning or crossing of underground pipelines.5. Effectively prevent accidental excavation and increase the speed of emergency repairs.6. Implement dynamic management of underground pipeline information.6. Underground Pipeline Electronic IdentifierThe electronic identifier is one of the core components of the pipeline electronic identification system. It can be buried near major underground facilities during construction, or used to mark existing underground facilities during pipeline maintenance. By applying the underground pipeline identification system, operators no longer need ground reference points, and no longer need to spend a lot of time and money searching for various underground facilities buried underground. This can greatly improve work efficiency and ensure safe production.The internal circuit of the electronic identifier is passive. The shell is waterproof, corrosion-resistant and shockproof. It can fully withstand drastic changes in the external environment. The normal service life of the electronic identifier can reach over 50 years, far exceeding the operational lifespan of the corresponding underground pipelines. It can achieve lifelong maintenance-free operation.

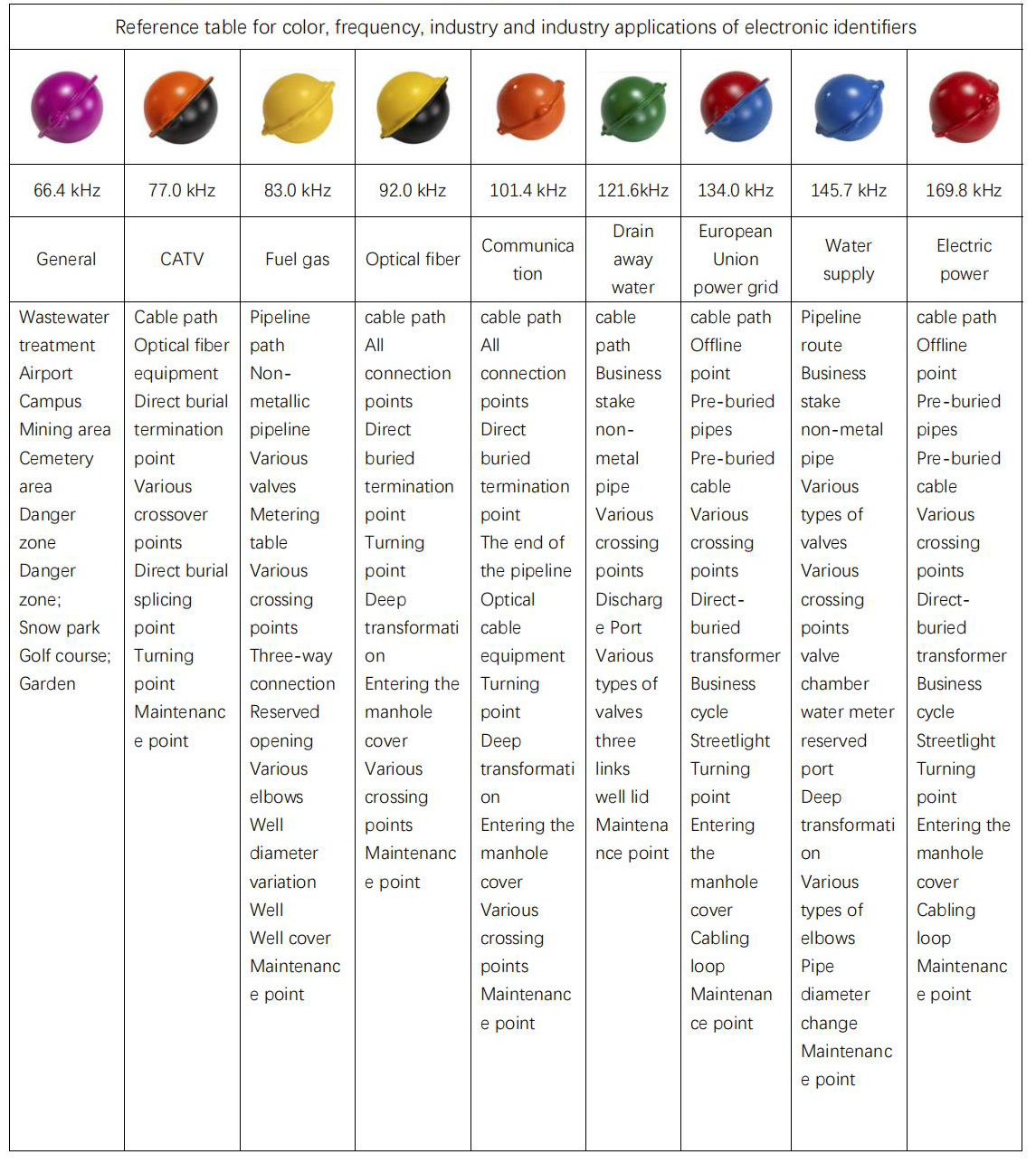

The underground pipeline electronic identification system can help operators achieve precise positioning and management of underground assets under non-digging conditions.1. Real-time access to the precise routing system of underground Pipelines.2. Quickly locate the target facilities on-site, such as valves, T-shaped branches, and joints.3. Quickly identify different underground pipelines and facilities.4. Quickly grasp the various complex situations such as the turning or crossing of underground pipelines.5. Effectively prevent accidental excavation and increase the speed of emergency repairs.6. Implement dynamic management of underground pipeline information.6. Underground Pipeline Electronic IdentifierThe electronic identifier is one of the core components of the pipeline electronic identification system. It can be buried near major underground facilities during construction, or used to mark existing underground facilities during pipeline maintenance. By applying the underground pipeline identification system, operators no longer need ground reference points, and no longer need to spend a lot of time and money searching for various underground facilities buried underground. This can greatly improve work efficiency and ensure safe production.The internal circuit of the electronic identifier is passive. The shell is waterproof, corrosion-resistant and shockproof. It can fully withstand drastic changes in the external environment. The normal service life of the electronic identifier can reach over 50 years, far exceeding the operational lifespan of the corresponding underground pipelines. It can achieve lifelong maintenance-free operation. Electronic identifiers can be classified into two categories:1. Ordinary electronic identifier:Allow users to mark the pipeline routes and important underground facilities during the construction and maintenance of underground pipelines, so as to accurately locate the routes and conduct depth detection of underground pipelines in the future.2. Electronic identifier with ID:It is equipped with a readable and writable RFID chip. When it is manufactured, a globally unique identification code (ID) is preset. The relevant information of underground facilities can also be pre-written into the chip, such as: the owner of the underground facility, the type of the facility, the description of the facility, the identification number of the facility, the implementation size, the pipeline direction, the installation or maintenance date, the relative depth, and the ID code. The stored information can be read by a detector. A power company decided to convert the following content into code and input it into the electronic identification device:

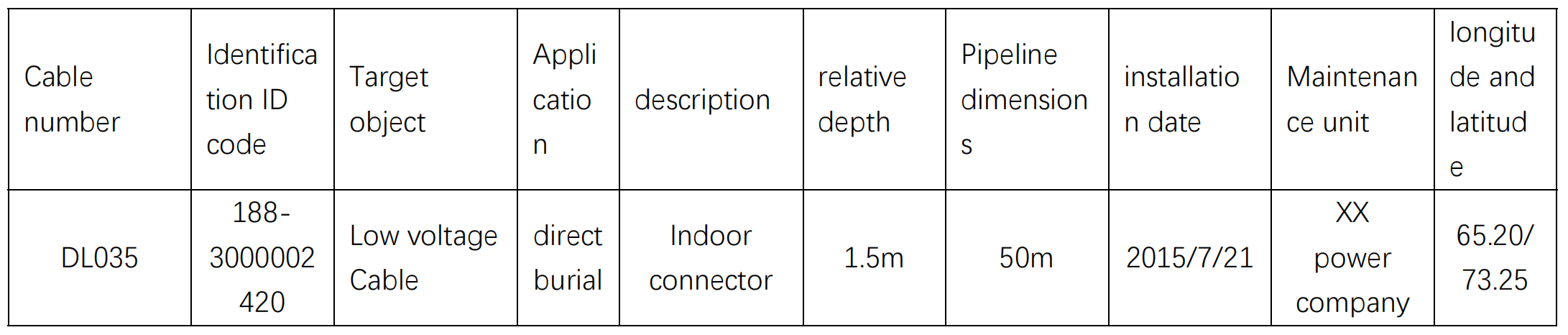

Electronic identifiers can be classified into two categories:1. Ordinary electronic identifier:Allow users to mark the pipeline routes and important underground facilities during the construction and maintenance of underground pipelines, so as to accurately locate the routes and conduct depth detection of underground pipelines in the future.2. Electronic identifier with ID:It is equipped with a readable and writable RFID chip. When it is manufactured, a globally unique identification code (ID) is preset. The relevant information of underground facilities can also be pre-written into the chip, such as: the owner of the underground facility, the type of the facility, the description of the facility, the identification number of the facility, the implementation size, the pipeline direction, the installation or maintenance date, the relative depth, and the ID code. The stored information can be read by a detector. A power company decided to convert the following content into code and input it into the electronic identification device: Color, frequency and usage environment of the electronic identifier:The underground pipeline electronic identification system is widely used in various industries. Based on the AWPA standards, the frequency and color codes have been formulated. We have developed 7 different frequency electronic identifiers for industries such as communication, power, cable TV, water supply, drainage, and gas, which are used to mark various underground facilities.

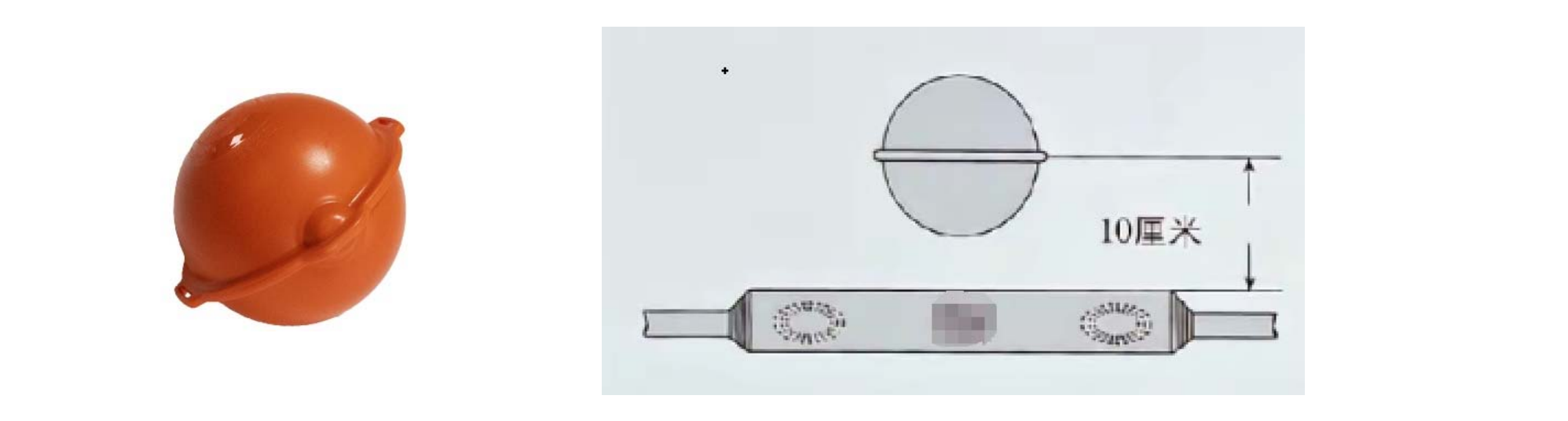

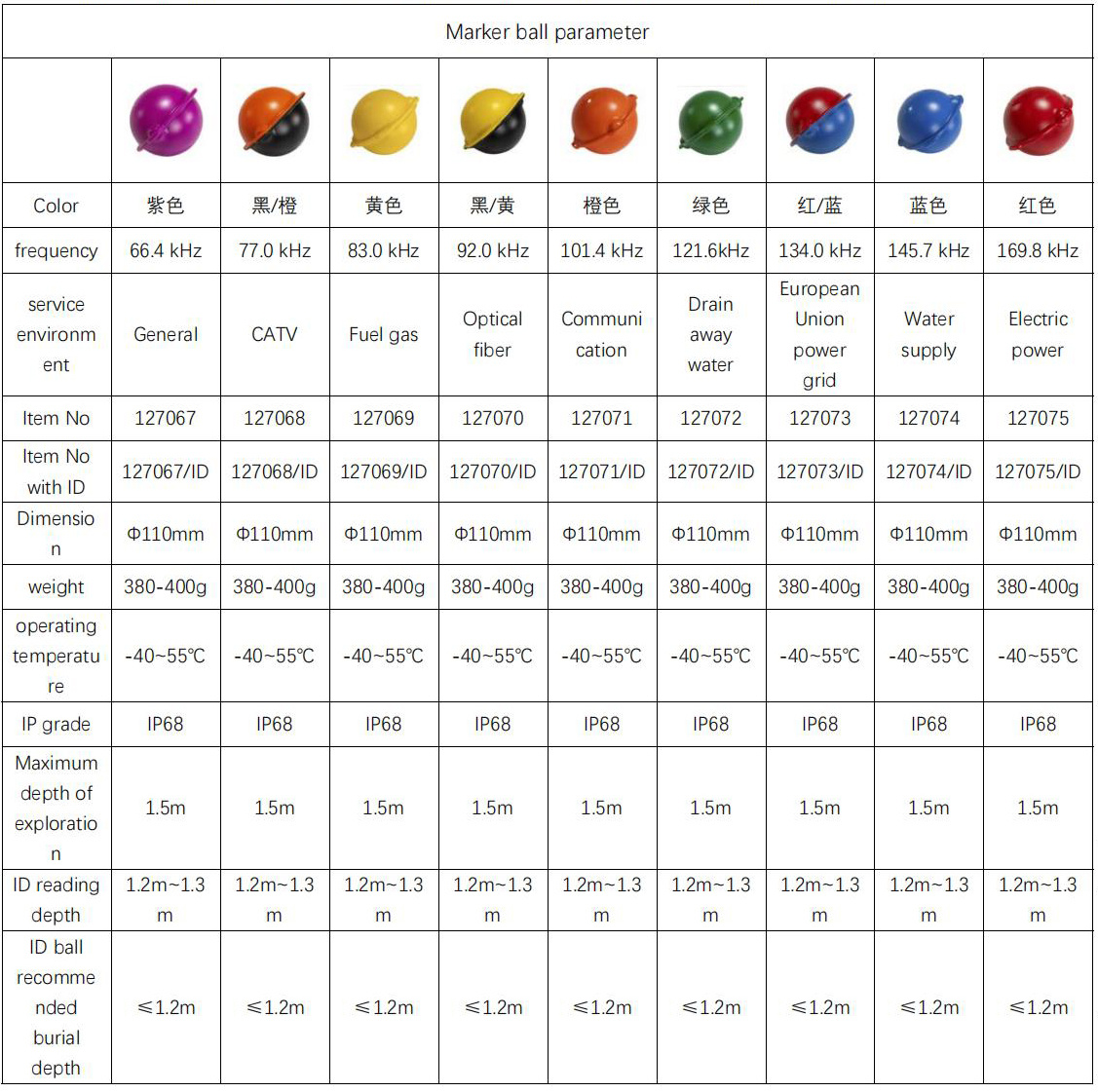

Color, frequency and usage environment of the electronic identifier:The underground pipeline electronic identification system is widely used in various industries. Based on the AWPA standards, the frequency and color codes have been formulated. We have developed 7 different frequency electronic identifiers for industries such as communication, power, cable TV, water supply, drainage, and gas, which are used to mark various underground facilities. 7. Type of Electronic IdentifierMarker ballThe flexible self-leveling design ensures that the electromagnetic induction coils inside the spherical marker remain at a horizontal position regardless of the angle at which the marker is inserted into the excavated ditch. This guarantees the most stable reception effect and detection depth. The anti-freezing liquid in the spherical marker enables it to be used in extremely cold environments as low as -40℃.

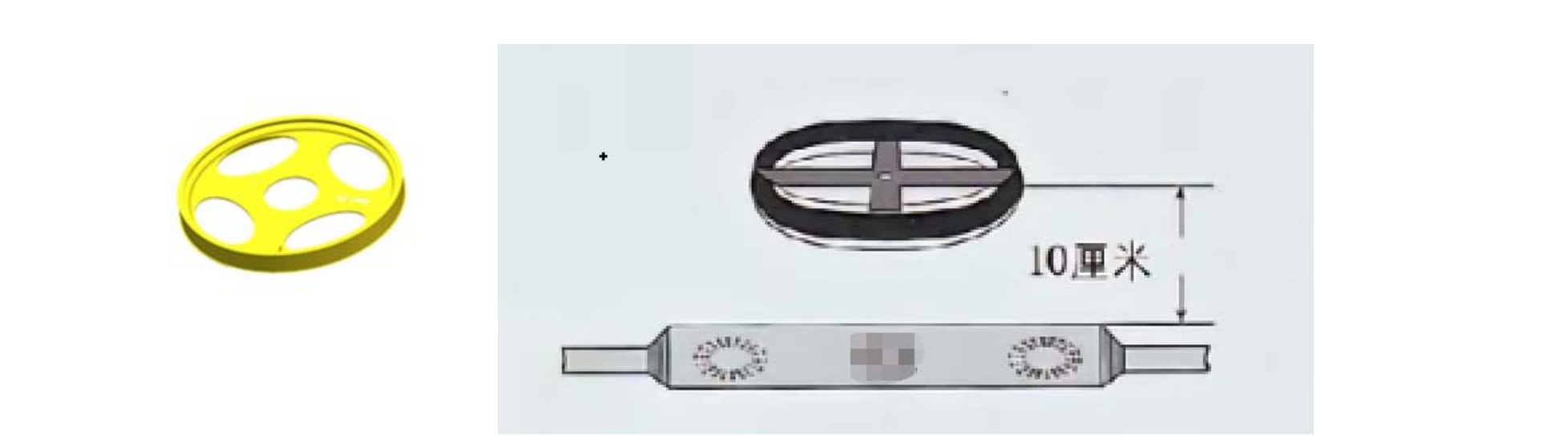

7. Type of Electronic IdentifierMarker ballThe flexible self-leveling design ensures that the electromagnetic induction coils inside the spherical marker remain at a horizontal position regardless of the angle at which the marker is inserted into the excavated ditch. This guarantees the most stable reception effect and detection depth. The anti-freezing liquid in the spherical marker enables it to be used in extremely cold environments as low as -40℃. Marker ball widely used in:1. High-density underground pipeline system in the city.2. Rural areas with few ground references.3. Areas that are difficult for non-metallic and traditional electromagnetic positioning devices to effectively detect.4. Key systems, life support systems and digital city systems.Features: Outer diameter 10 cm. Maximum measurement depth 1.5 meters. It is recommended to maintain aminimum distance of 10 cm from the marked object (measured from the center of the ball)

Marker ball widely used in:1. High-density underground pipeline system in the city.2. Rural areas with few ground references.3. Areas that are difficult for non-metallic and traditional electromagnetic positioning devices to effectively detect.4. Key systems, life support systems and digital city systems.Features: Outer diameter 10 cm. Maximum measurement depth 1.5 meters. It is recommended to maintain aminimum distance of 10 cm from the marked object (measured from the center of the ball) Other types of identifiersTaking into account the various needs of our customers, in addition to the spherical electronic identifier, we have also developed cylindrical identifiers and disc-shaped identifiers. The main difference lies in the detection distance and installation method.Nail marker:

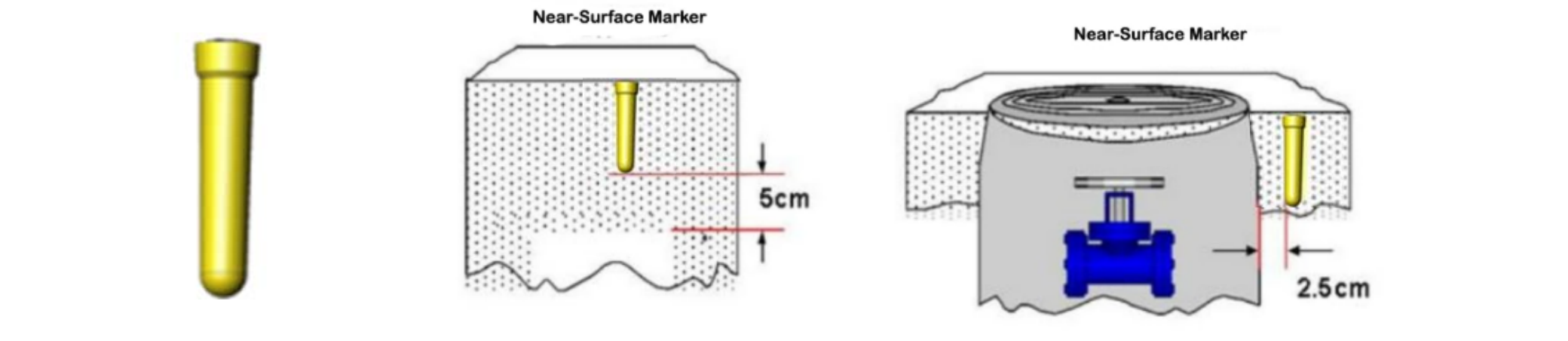

Other types of identifiersTaking into account the various needs of our customers, in addition to the spherical electronic identifier, we have also developed cylindrical identifiers and disc-shaped identifiers. The main difference lies in the detection distance and installation method.Nail marker: The recommended burial depth is 0.6 meters. This allows users to easily mark the existing underground facilities. The nail-type marker must be installed vertically within the drilled hole. The diameter is 2 cm, the length is 7.6 cm, the maximum measurable depth is 0.6 meters, and it is recommended to maintain a minimum vertical distance of 5 cm from the marked object.Disc-shaped marker:

The recommended burial depth is 0.6 meters. This allows users to easily mark the existing underground facilities. The nail-type marker must be installed vertically within the drilled hole. The diameter is 2 cm, the length is 7.6 cm, the maximum measurable depth is 0.6 meters, and it is recommended to maintain a minimum vertical distance of 5 cm from the marked object.Disc-shaped marker: The disc-shaped identifier is suitable for low-density, high-buried underground facilities, such as connection points, maintenance points, cable storage, service piles, and underground pipeline routes beyon the detection depth of the spherical identifier. Due to its relatively large size, it is usually suitable for excavating large areas rather than being used in narrow trenches.Diameter 21 cm, thickness 3 cm, maximum measurable depth 1.8 meters, and it is recommended to maintain a minimum distance of 10 cm from the identified object.

The disc-shaped identifier is suitable for low-density, high-buried underground facilities, such as connection points, maintenance points, cable storage, service piles, and underground pipeline routes beyon the detection depth of the spherical identifier. Due to its relatively large size, it is usually suitable for excavating large areas rather than being used in narrow trenches.Diameter 21 cm, thickness 3 cm, maximum measurable depth 1.8 meters, and it is recommended to maintain a minimum distance of 10 cm from the identified object.

Tag: