LOOSE TUBE LAYER STRANDED REINFORCED ARMORED FIBER OPTIC CABLE GYTA53

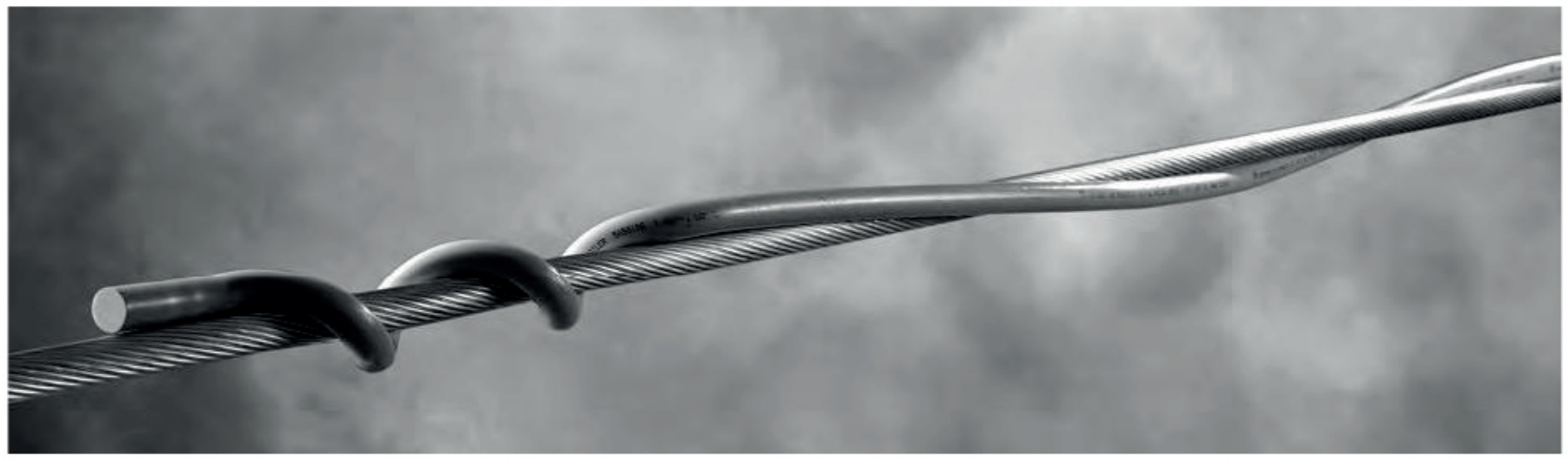

The structure of the GYTA53 fiber optic cable is that the 250μm fiber is sleeved into a loose tube made of high modulus material, and the loose tube is filled with a waterproof compound. The center of the cable core is a metal reinforced core. For some optical cables with a certain number of cores, a layer of polyethylene (PE) needs to be squeezed out of the metal reinforced core. The loose tube (and filler rope) is twisted around the central reinforced core to form a compact and round cable core, and the gaps in the cable core are filled with water blocking filler. Plastic-coated aluminum tape (APL) is longitudinally wrapped and then extruded with a layer of polyethylene inner sheath, and double-sided plastic-coated steel tape (PSP) is longitudinally wrapped and then extruded with polyethylene sheath to form a cable.

Keyword:Optical fiber cable,Optical cable fittings,Data cable

- Commodity name: LOOSE TUBE LAYER STRANDED REINFORCED ARMORED FIBER OPTIC CABLE GYTA53

- Description

-

Description

The structure of the GYTA53 fiber optic cable is that the 250μm fiber is sleeved into a loose tube made of high modulus material, and the loose tube is filled with a waterproof compound. The center of the cable core is a metal reinforced core. For some optical cables with a certain number of cores, a layer of polyethylene (PE) needs to be squeezed out of the metal reinforced core. The loose tube (and filler rope) is twisted around the central reinforced core to form a compact and round cable core, and the gaps in the cable core are filled with water blocking filler. Plastic-coated aluminum tape (APL) is longitudinally wrapped and then extruded with a layer of polyethylene inner sheath, and double-sided plastic-coated steel tape (PSP) is longitudinally wrapped and then extruded with polyethylene sheath to form a cable.

Features

① has good mechanical properties and temperature characteristics

②The pine casing material itself has good hydrolysis resistance and high strength

③ Single steel wire as longitudinal central strength member

④ Good pressure resistance and softness

⑤ Corrugated steel belt longitudinally wraps the cable core to provide good compression resistance

⑥ PE sheath has good anti-ultraviolet function ⑦ complete core filling

⑧ Aluminum strip (APL) moisture barrier

optical characteristics

Project G.652 G.655 50/125um 625/125un Attenuation @850nm ≤ 3.0dB/km ≤ 3.2dB/km @1300nm ≤ 1.0dB/km ≤ 1.2dB/km @1310nm ≤ 0.36dB/km ≤ 0.40dB/km @1550nm ≤ 0.22dB/km ≤ 0.23dB/km Bandwidth @850nm ≥500MHZ.km ≥200MHZ.km @1300nm ≥1000MHZ.km ≥600MHZ.km numerical aperture 0.200±0.015NA 0.275±0.015NA cut-off wavelength ≤ 1260mn ≤ 1450mn Structural Parameters

Model Number of optical fiber cores Casing Filling rope Diameter (mm) Weight (kg/km) Tensile force

Long Term/Short Term

(N)Anti-pressure

Long Term/Short Term

(N/100mm)Bending radius

Static/Dynamic

(Mm)GYTA53-2~6 2~6 1 5 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-8~12 8~12 2 4 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-14~18 14~18 3 3 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-20~24 20~24 4 2 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-26~30 26~30 5 1 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-32~36 32~36 6 0 13.5 190 1000/3000 1000/3000 12.5D/25D GYTA53-38~48 38~48 4 2 13.9 190 1000/3000 1000/3000 12.5D/25D GYTA53-50~60 50~60 5 1 13.9 190 1000/3000 1000/3000 12.5D/25D GYTA53-62~72 62~72 6 0 13.9 190 1000/3000 1000/3000 12.5D/25D GYTA53-86~96 86~96 8 0 15.1 260 1000/3000 1000/3000 12.5D/25D GYTA53-134~144 134~144 12 0 17.6 340 1000/3000 1000/3000 12.5D/25D Environmental Performance

Working temperature:-40~70 ℃

Storage temperature:-40~70 ℃

Standard

In line with YD/T901, IEC 60794-1 and other standards.

Tag: