ALL-DIELECTRIC SELF-SUPPORTING FIBER OPTIC CABLE ADSS

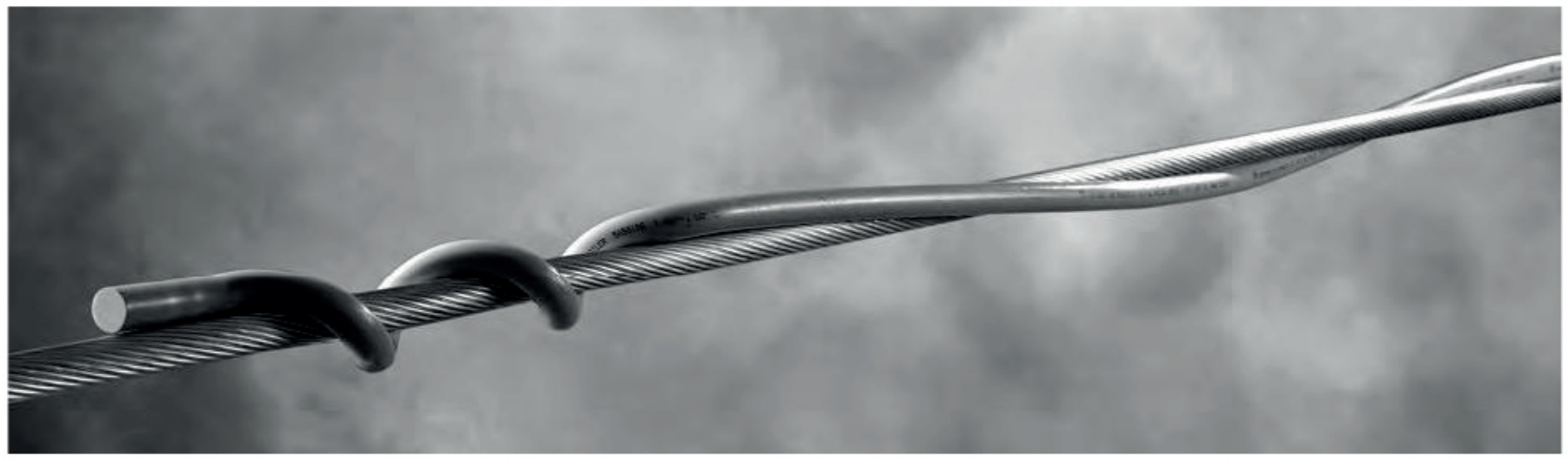

ADSS optical cable adopts loose layer stranded structure, 250 μm optical fiber is sleeved into a loose tube made of high modulus material, and the loose tube is filled with waterproof compound. The loose tube (and filler rope) is twisted around the non-metallic central reinforced core (FRP) to form a compact cable core, and the gap of the cable core is filled with water-blocking grease. The polyethylene (PE) inner sheath is extruded outside the cable core, then the aramid fiber with reinforcing effect is twisted, and finally the polyethylene (PE) outer sheath or the electric trace resistance (AT) outer sheath is extruded. The design of ADSS optical cable fully considers the actual situation of power lines and is suitable for different levels of high-voltage transmission lines. Polyethylene (PE) sheath can be used for 10kV and 35kV power lines. For 110kV and 220kV power lines, the hanging point of optical cable must be determined by calculating the distribution of electric field strength and the outer sheath of electrical trace resistance (AT) must be adopted. At the same time, the amount of aramid fiber and the perfect stranding process are carefully designed to meet the application requirements of different spans.

Keyword:Optical fiber cable,Optical cable fittings,Data cable

- Commodity name: ALL-DIELECTRIC SELF-SUPPORTING FIBER OPTIC CABLE ADSS

- Description

-

Description

ADSS optical cable adopts loose layer stranded structure, 250 μm optical fiber is sleeved into a loose tube made of high modulus material, and the loose tube is filled with waterproof compound. The loose tube (and filler rope) is twisted around the non-metallic central reinforced core (FRP) to form a compact cable core, and the gap of the cable core is filled with water-blocking grease. The polyethylene (PE) inner sheath is extruded outside the cable core, then the aramid fiber with reinforcing effect is twisted, and finally the polyethylene (PE) outer sheath or the electric trace resistance (AT) outer sheath is extruded. The design of ADSS optical cable fully considers the actual situation of power lines and is suitable for different levels of high-voltage transmission lines. Polyethylene (PE) sheath can be used for 10kV and 35kV power lines. For 110kV and 220kV power lines, the hanging point of optical cable must be determined by calculating the distribution of electric field strength and the outer sheath of electrical trace resistance (AT) must be adopted. At the same time, the amount of aramid fiber and the perfect stranding process are carefully designed to meet the application requirements of different spans.

Features

① It can be erected continuously. Life expectancy over 30 years

② Use AT sheath,improved tracking resistance performance, light weight, small cable diameter, reduce the influence of ice and wind , and the load on the tower and support are reduced, with large span.

③ It has excellent tensile properties and temperature characteristics.

Adaptation to meteorological conditions

Meteorological conditions A B C D Wind speed (m/s) 25 35 10 10 Icing (m/s) 0 0 5 10 Additional load (N/m) 0.7 0.7 2.5 4.4 Optical Characteristics

Item G.652 G.655 50/125μm 62.5/125μm Attenuation @850nm ≤ 3.0dB/km ≤ 3.2db/Km @1300nm ≤ 1.0dB/km ≤ 1.2db/Km @1310nm ≤ 0.36dB/km ≤ 0.40dB/km @1550nm ≤ 0.22dB/km ≤ 0.23dB/km Bandwidth @850nm ≥500MHZ.km ≥200MHZ.km @1300nm ≥ 1000MHZ km ≥600MHZ.km Numerical aperture 0.200±0.015NA 0.275±0.015NA Cable cut-off wavelength ≤ 1260mm ≤ 1450mm Structural Parameters

Reference outside diameter

(Mm)Rated breaking force RTS (kN) Maximum allowable service pulling force Sectional area of tensile element

(mm2)Modulus of elasticity

(kN/mm2)Coefficient of thermal expansion Span(m) to adapt to meteorological conditions

Weight

(kg/km)A B C D PE AT 11.8 10 4 4.6 7.6 1.8 160 100 140 100 117 124 12 15 6 7.6 8.3 1.5 230 150 200 150 121 129 12.3 20 8 10.35 9.45 1.3 300 200 290 200 126 134 12.6 24 10 13.8 10.8 1.2 370 250 350 250 133 141 12.8 30 12 14.3 11.8 1 420 280 400 280 138 145 13.1 36 15 18.4 13.6 0.9 480 320 460 320 145 153 13.5 45 18 22 16.4 0.6 570 380 550 380 155 163 13.8 53 22 26.4 18 0.3 670 460 650 460 163 171 14.4 60 26 32.2 19.1 0.1 750 530 750 510 177 186 14.6 70 28 33 19.6 0.1 800 560 800 560 182 191 14.8 85 34 40 20.1 0.1 880 650 880 650 195 204

Tag: